Peak Load Logger Indicator

Product Details:

- Alarm Audio-Visual Overload Alarm

- Temperature Range 0C to 50C

- Theory Strain Gauge Principle

- Data Capacity 5000 records

- Power Supply AC 100-240 V, 50/60 Hz adapter; internal battery

- Type Peak Load Logger Indicator

- Display Type Digital LCD Display

- Click to View more

Peak Load Logger Indicator Price And Quantity

Peak Load Logger Indicator Product Specifications

- Audio-Visual Overload Alarm

- 0.5% F.S.

- Peak Load Logger Indicator

- 220 mm x 150 mm x 80 mm

- 0 to 10000 kg

- 1 kg

- 0C to 50C

- USB / RS232

- Digital LCD Display

- Strain Gauge Principle

- 5000 records

- Built-in memory for data logging

- Main unit, USB cable, software CD, instruction manual

- 1.5 kg

- AC 100-240 V, 50/60 Hz adapter; internal battery

- No

- Up to 100 hours

- Rechargeable Lithium-Ion battery

Product Description

Banking upon the strength and caliber of our experienced and skilled team of professionals, we have become a noteworthy manufacturer and trader of a huger gamut of Peak Load Logger Indicator. These machines are designed and manufactured keeping in mind all the set quality norms of the industry. Also, we develop these machines with the help of superior-grade basic material and other components which are obtained from the genuine vendors of the industry. Furthermore, our range of Peak Load Logger Indicator is best known for features such as operational efficiency, robust design and so on.

Model code:CT-904

Product Name:Universal Testing Machine

Category:peak_load Indicators_loggers

Sub Category:peak_load_indicators

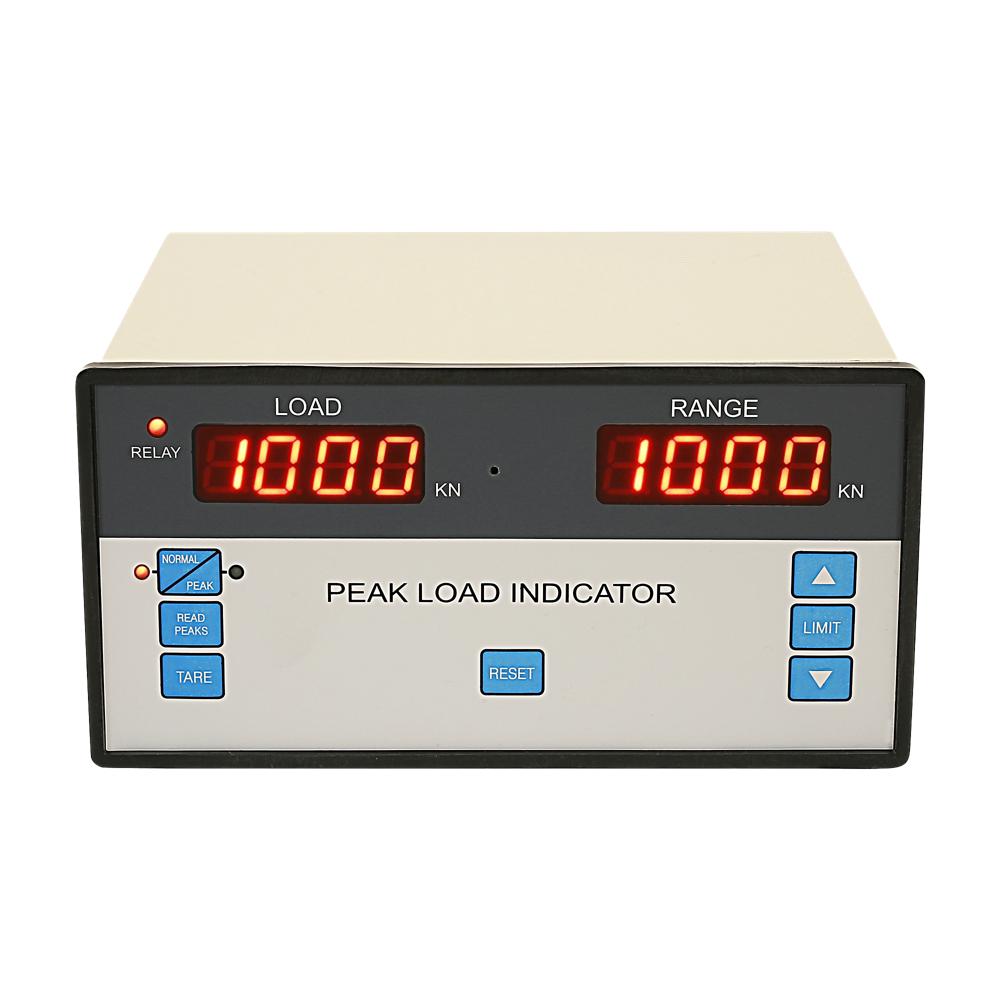

Features

- Separate displays for load indication and displacement

- Range for load indication corresponding to 4-20mA input digitally settable from front panel

- Calibration of displacement for different rotary encoders

- Peak/Normal mode selectable

- Up to 9 peaks can be recorded and recalled for Load and Displacement

- Buzzer annunciation at Peak

- Relay output for cut-off protection for load, displacement as well as breaking load

- Digital tare for load and displacement provided to remove initial error

- Non-volatile memory for saving configuration

- Configuration lock at rear to prevent tampering with Range

- Aesthetically designed front panel with membrane switches

Specification;

| Display | 4 Digit 0.56 7 segment Red LED display for Load (KN) |

| Range | Load: 1KN to Range |

| Accuracy | 0.1% of Full Scale 1 digit |

| Input | From 2 wire loop transmitter giving 4-20mA output, 4-20mA input => 0 Range |

| Relay Logic | Relay ON for |

| Normal/Peak Mode | Selectable from front panel with LED indication of mode |

| Peak Read | 9 peaks of both load and displacement with facility to reset memory |

| Peak Detection | Peak hold is resettable from front Reset Switch or by a rear external contact |

| Tare Facility (Zero) | Digital Tare using front panel Tare switch (for removing initial error). Tare also resets Displacement to Zero |

| Memory | Non-volatile EEPROM to save settings |

| Configuration Lock | On rear terminals to prevent unauthorized/accidental alteration of Range using front switches |

| Supply | 220V AC 15% @ 50/60Hz |

| Dimensions | Front Fascia: 96mm x 192mm |

Advanced Data Logging and Storage

This indicator allows users to select data logging intervals from 1 second up to 60 minutes, accommodating a range of testing and reporting needs. Its built-in memory supports up to 5,000 records, each time-stamped using a real-time clock. Data can easily be exported as CSV or TXT files for straightforward analysis and documentation.

Robust Performance and Portability

Housed in durable ABS plastic, the device withstands operating humidity up to 85% RH and temperatures from 0C to 50C. You can mount it on a bench top or operate it portably, with a rechargeable lithium-ion battery providing up to 100 hours of standby time. This flexibility makes it suitable for field or laboratory settings.

User-Friendly Operation and Accurate Results

Ease of use is assured through automatic/manual calibration, digital LCD display, and audio-visual alarms for overload. The device interfaces via USB or RS232 and is compatible with Windows-based software. Its resolution of 1 kg and accuracy of 0.5% F.S. support precise data collection for demanding applications.

FAQs of Peak Load Logger Indicator:

Q: How do I select the data logging interval on the Peak Load Logger Indicator?

A: Data logging intervals are easily adjustable from 1 second to 60 minutes using the devices interface or compatible Windows software. This flexibility helps tailor recording to your specific project requirements.Q: What benefit does the real-time clock and time-stamped data provide?

A: The integrated real-time clock ensures every recorded measurement is accurately time-stamped. This feature supports reliable data tracking and simplifies compliance with quality management or audit requirements.Q: When is it necessary to perform manual calibration?

A: Manual calibration is recommended when first installing the device, after extended periods of use, or if environmental conditions change significantly. Automatic calibration is suitable for routine adjustments.Q: Where can I use this indicator, and does it support portable operation?

A: Thanks to its robust housing and rechargeable battery, the device can be used on bench tops in laboratories or transported to field sites. Portable use is supported by up to 100 hours of standby time.Q: What is the process for exporting logged data from the device?

A: Logged data can be exported via either the USB or RS232 interface. The software provided (Windows 7, 8, 10 compatible) enables records to be saved in CSV or TXT formats for further analysis or reporting.Q: How does the indicator provide overload protection and alerts?

A: The device features maximum overload protection up to 150% of full scale and audio-visual alarms. Indicator lights signal the user if power is on, memory is full, or overload conditions are detected, facilitating safe operation.Q: What are the main usage scenarios and benefits for exporters, manufacturers, and suppliers?

A: This instrument is ideal for process monitoring, material testing, or quality control in manufacturing and export operations. Its portability, memory capacity, and accurate logging support efficient handling of batch records and compliance documentation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+