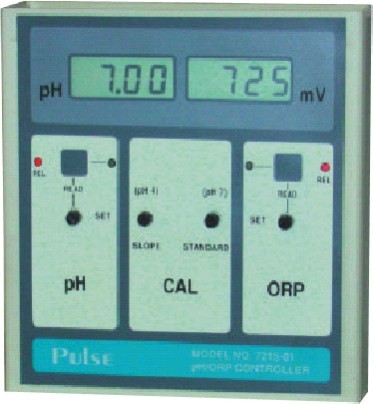

pH and ORP Controller

Product Details:

- Connection BNC connector for electrode, Terminal blocks for relay and power

- Accuracy 0.01 pH; 1 mV ORP

- Pressure 0~6 bar (sensor dependent)

- Function To monitor and control pH and ORP (Oxidation Reduction Potential) levels in liquids.

- Size 96 mm x 96 mm x 110 mm (Panel Mountable)

- Click to View more

pH and ORP Controller Product Specifications

- BNC connector for electrode, Terminal blocks for relay and power

- To monitor and control pH and ORP (Oxidation Reduction Potential) levels in liquids.

- 0.01 pH; 1 mV ORP

- 96 mm x 96 mm x 110 mm (Panel Mountable)

- 0~6 bar (sensor dependent)

Product Description

We are presenting a vast series of pH and ORP Controller. It is availed in custom made solutions to meet the current needs of consumers. This controller is designed for water treatment and swimming pool applications. It indicates to monitor the Ph. It is use in laboratories and process control applications. pH and ORP Controller is highly compatible to utilized for a longer time. It is basically providing a complete solution for ph and orp controlling applications.

Specification

| pH Range | 0.00 14.00pH |

| pH Resolution | 0.01pH |

| pH Control | Adjustable set point in range 5.20 10.00pH |

| ORP Range | +/- 1999mV ORP |

| ORP Resolution | +/-1mV ORP |

| ORP Control | Adjustable set point in range 200 600mV (can be modified) |

| Display | pH LCD / H=1 /2 (12.5mm), ORP LCD / |

| Dimensions | 6.2x 6.7x 2.2 (WxHxD) |

| Weight | 1.7Lbs. / 0.8kg |

| Power Consumption | 115VAC/60Hz / 0.25Amp |

| pH and ORP outlets | 115VAC/60Hz / Maximum 5 Amp. per outlet |

Advanced Monitoring and Control Functions

The dual-channel digital LCD display offers simultaneous monitoring of pH and ORP, crucial for process industries and water treatment plants. The two relay outputs allow for automated control based on user-defined set points, enabling the management of dosing pumps or alarms, thus safeguarding systems from undesirable chemical imbalances.

User-Friendly Calibration and Operation

Manual calibration is performed directly through the front panel, ensuring straightforward adjustments without the need for specialized tools. Temperature compensation can be selected as manual or upgraded to automatic, optimizing accuracy across varying operating conditions. BNC connectors facilitate quick electrode installation, while terminal blocks simplify relay and power connections.

Durable and Adaptable Design

Encased in tough ABS plastic and rated IP65 at the front panel, the controller is resistant to dust and humidity, suitable for rigorous environments. Its panel-mountable size ensures compatibility with standard control boards, and the flexible power supply (230V AC) and broad measuring ranges cater to diverse industrial settings.

FAQs of pH and ORP Controller:

Q: How does the pH and ORP Controller with Display operate?

A: The controller continuously monitors the pH and ORP levels in liquids via compatible electrodes. It displays the readings on a digital LCD screen and can activate two relay outputs, allowing you to control external devices such as dosing pumps based on preset high or low values.Q: What is the calibration process for this controller?

A: Calibration is performed manually through the front panel interface, letting users adjust readings for both pH and ORP to ensure accuracy. Calibration solutions for pH and ORP should be used according to the manufacturers instructions.Q: When should the controller be used in an industrial setting?

A: This device is ideally used whenever precise monitoring and control of liquid pH and ORP is neededsuch as in water treatment plants, chemical processes, and laboratories. It can be set to activate alarms or pumps when readings exceed safe thresholds.Q: Where is the controller typically installed?

A: The controller is designed for panel mounting and can be placed in control rooms, process panels, or field enclosures. Its compact size (96 mm x 96 mm x 110 mm) ensures seamless integration into standard industrial panels.Q: What are the benefits of dual relay outputs?

A: Dual relay outputs enable independent high and low set points for both pH and ORP control. This provides automatic corrective actions such as dosing, mixing, or alarms, enhancing process safety and reducing manual intervention.Q: How is temperature compensation handled by this device?

A: The controller offers manual temperature compensation as standard, with the option to upgrade to automatic compensation. This ensures measurement accuracy despite temperature fluctuations in the liquid being monitored.Q: What makes this controller suitable for harsh industrial environments?

A: It features an ABS plastic enclosure with an IP65-rated front panel, making it resistant to dust and splashes. This, along with a pressure-compatible design (0~6 bar, sensor dependent), makes it suitable for use in demanding industrial settings across India.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+